Understanding Corrosion in Water Treatment and How Soltellus™ Polymers Overcome It

A Comprehensive Guide to Corrosion Inhibition in Water Treatment with Soltellus™

August 21, 2024

4 minutes

Water Treatment

By Sierra Cotton

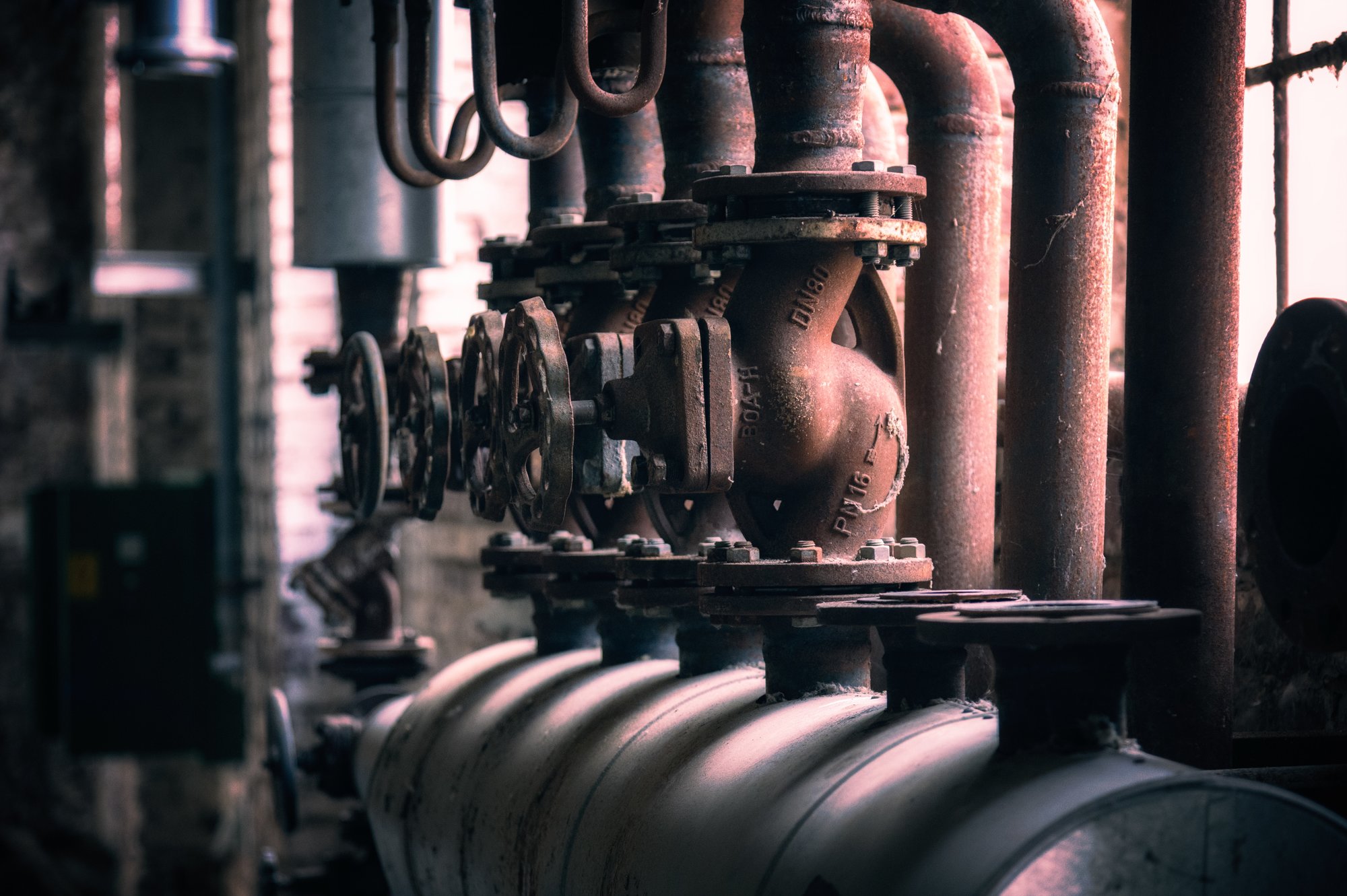

Download Free Water Treatment GuideCorrosion in water treatment systems presents a significant challenge that can lead to reduced efficiency, increased maintenance costs, and premature equipment failure. Corrosion is a natural process that results from the interaction between a metal and its environment, leading to a gradual degradation of the material. Managing this process is crucial for maintaining the integrity and longevity of water treatment infrastructure.

Types of Corrosion in Water Treatment Systems

Uniform Corrosion

Uniform corrosion occurs across the entire exposed surface of a metal at a steady rate. It is frequently observed in pipes and tanks that are part of municipal water treatment facilities, where exposure to acidic and alkaline waters is common. This type of corrosion can lead to the thinning of metal, reducing its structural integrity and lifespan. Systems that handle water with fluctuating pH levels are particularly susceptible to this form of corrosion, necessitating regular monitoring and maintenance.

Pitting Corrosion

Pitting corrosion is characterized by the formation of small, localized areas of corrosion that penetrate the metal surface. It is particularly prevalent in systems exposed to seawater or that use chloride-containing chemicals in water treatment processes, such as those found in coastal water treatment plants or industrial settings near the ocean. The localized damage from pitting corrosion can lead to leaks or system failures, especially in stainless steel components that are generally resistant to uniform corrosion and vulnerable to chloride-induced pitting.

Galvanic Corrosion

Galvanic corrosion arises when two dissimilar metals are electrically connected in the presence of an electrolyte, such as the water in cooling systems. It is commonly found in systems where metals such as copper and steel are used together, for example, in heat exchangers or water pipes. The less noble metal (anode) corrodes faster, while the more noble metal (cathode) is protected.

Crevice Corrosion

Crevice corrosion occurs in shielded areas where stagnant electrolytes accumulate, such as under gaskets or bolt heads. This form of corrosion is often seen in equipment with improper sealing or where small gaps are present. It can be particularly problematic in water treatment systems with numerous joints and connections, leading to unexpected failures due to its concealed nature.

Intergranular Corrosion

Intergranular corrosion affects the grain boundaries of stainless steel and other alloys, particularly after exposure to temperatures of about 500°C to 800°C, which can occur during welding. This type of corrosion is a concern in systems that involve welded pipes and tanks used in high-temperature environments, such as in boiler systems within industrial facilities.

Erosion Corrosion

Erosion corrosion results from the rapid removal of material caused by the combined action of corrosion and mechanical erosion, which is exacerbated by high fluid velocities or turbulence. It is typical in pumps, water turbines, and pipes where high-speed water flow is present. This type of corrosion can lead to premature wear and failure of parts, especially where abrupt changes in flow direction occur, creating turbulent flow that increases the erosive force on metal surfaces.

Mechanisms of Corrosion Control with Soltellus

Soltellus, comprised of polyaspartate, offers a sophisticated approach to managing corrosion in water treatment systems. Polyaspartates are known for their corrosion inhibition properties, particularly in systems susceptible to scale and corrosion. Polyaspartate addresses corrosion by various mechanisms.

Inhibition

Soltellus can form a protective film on the surface of metals, reducing the metal's exposure to corrosive elements. This film acts as a barrier that prevents the electrochemical processes necessary for corrosion.

Chelation

Soltellus is an effective chelating agent. It can bind with metal ions, such as iron, calcium, and magnesium, which are often involved in corrosion processes. By complexing with these ions, polyaspartates prevent them from participating in reactions that lead to corrosion.

Anodic Protection

By modifying the electrochemical environment on the metal surface, polyaspartates can shift the potential of the metal towards less oxidizing conditions, thereby preventing the anodic reaction that leads to corrosion.

Conclusion

Effective management of corrosion in water treatment systems is crucial for ensuring operational efficiency and longevity of the infrastructure. By understanding the types of corrosion and utilizing advanced solutions like Soltellus, facilities can significantly enhance their corrosion control strategies, leading to better system performance and reduced overall costs. This integrated approach not only protects physical assets but also supports the sustainability of water treatment operations.